Your cart is currently empty!

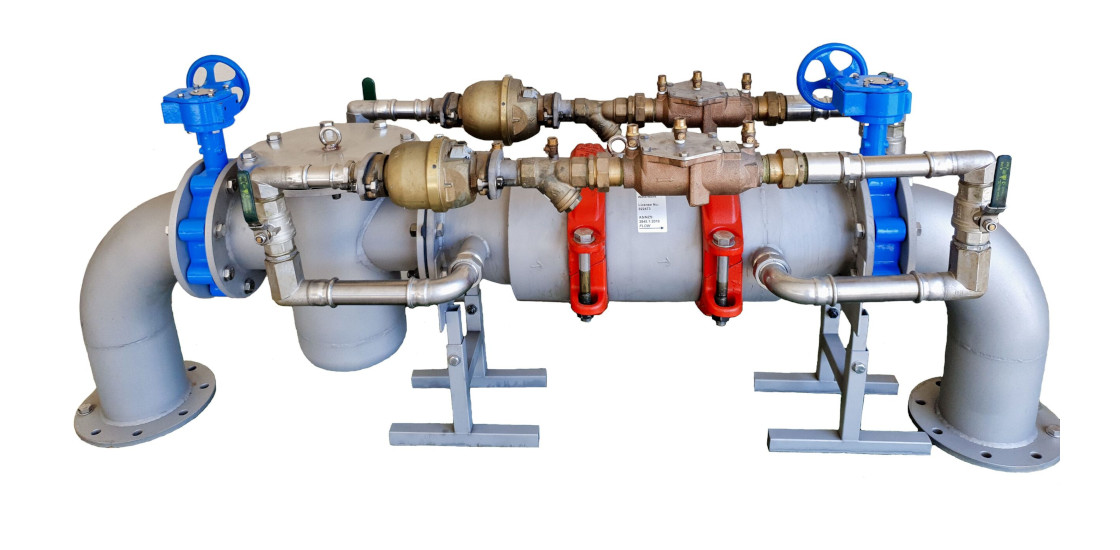

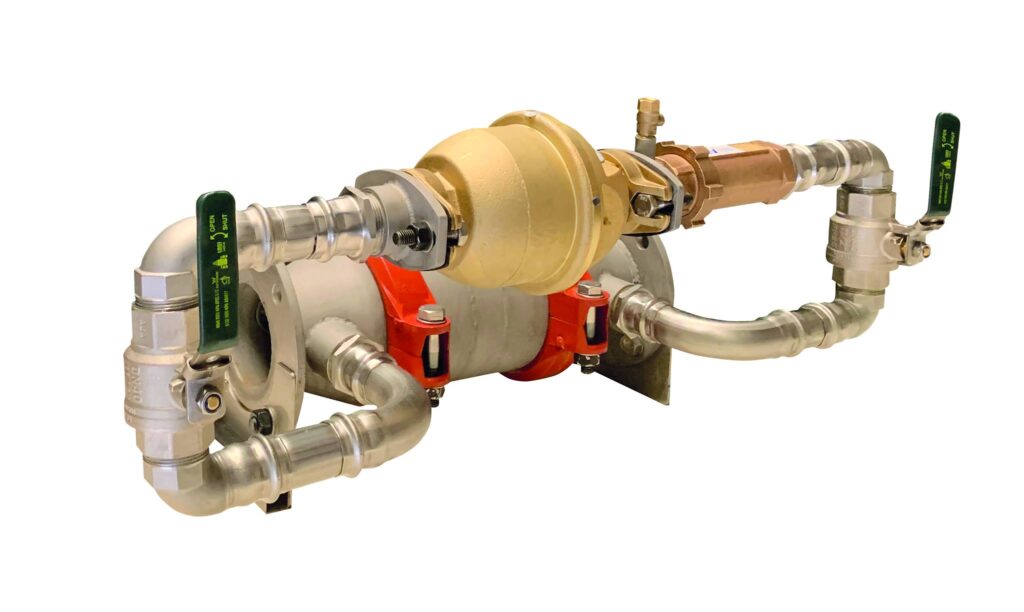

MetCheck Detector check valves

MetCheck detector check valves combine a check valve and a water meter.

Used mostly in commercial, industrial and group title premises, the MetCheck measures everyday potable water flows to the premises. Should excessive fire flows be required the main valve will open, allowing unrestricted water flow to fight the fire.

With various configurations of internal springs and water meters the MetCheck can be used in dedicated fire services for counting illegal use of water and water leaks, while preventing the backflow of stagnant water into the main potable system.

Alternatively the MetCheck can be used as a combined fire and potable water measuring system to schools, retirement villages, industrial and commercial sites allowing larger volumes of water to be delivered to more consumers.

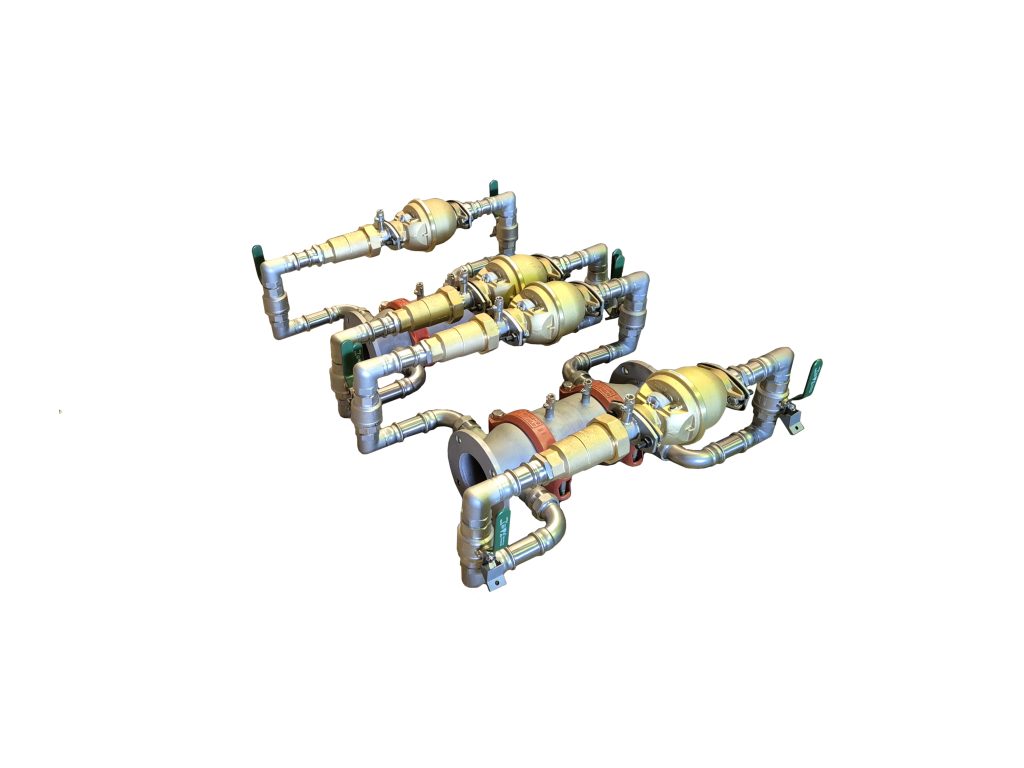

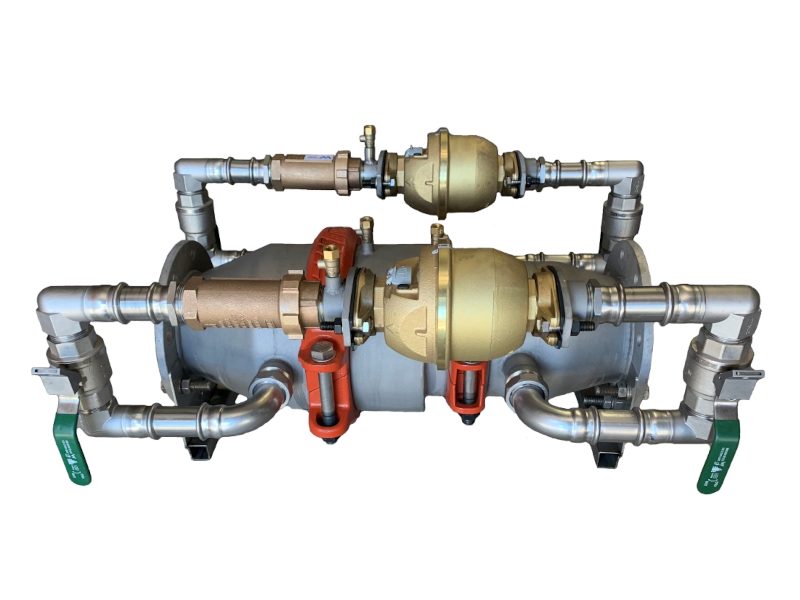

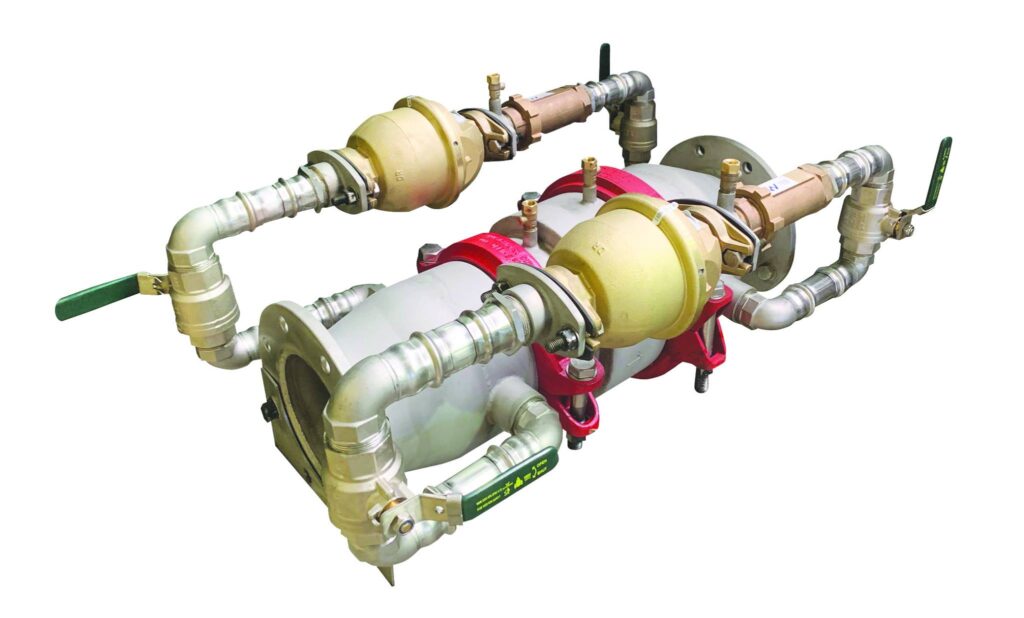

Available in 100mm – 150mm arrangements, with both flanged and roll grooved ends. The bypass assemblies are available in both twin and singles arrangements, made from the same high-quality stainless steel. Available in 20, 25, 32 & 40mm they are designed with all applications in mind.

Valve Images

Features

Details

| The valve Body is made from 316 Sch10 Stainless Steel to ensure the maximum resistance to corrosion with no rusting internal debris or blistering paint passing through checks, damaging seals, or causing severe damage to the internal componentry. |

| Valves can be returned to the Hydromet Factory for a 10-year service. New Serial numbers are used to record the valves history as part of the watermark accreditation. |

| Earth support tags can be supplied if current is suspected to be within the valve assembly of the pipe line. Earth leakage can reduce the life span of any valve assembly due to osmosis which will attack the valves close to weld lines. |

| Roll groove coupling body to ensures easy access when servicing check. A simplistic design allows for the check to remain in the valve with the tail being removed to access the rubbers. |

| Lead free |

| Top-mounted test taps to ensure ease of use when testing testing |

| By-Pass arrangements include Barrell unions at the body for easy removal in-order to service the valve |

| 5 Year warranty on the main body and a 12 Month Warranty on all moving parts. We are unable to cover components that are shown to be damaged by debris, or incorrect installation. E.g. installation for an electric cut off switch downstream causing corrosion. |

| Valves come with optional strainer boxes, valve support stands, Met-Coated Nuts and Bolts anti-galling specific for high tension applications, and numerous J & S -Pipe rises all in 316 Stainless Steel to accommodate a full assembly. |

| All Hydromet Valves are rated to PN16 in all models. |

| Ribbed seal anti-slip gaskets purposely designed by Hydromet. |

Accreditation

Details

We are pleased to advise Hydromet in recent times commissioned AWQC to carry out an updated and significant testing program of sampled components supplied into the marketplace on behalf of Hydromet, with the result of this testing program conforming with the requirements of AS/NZS 4020.

WaterMark Certification – NATA approved test reports form part of the conditions of WaterMark certification which is maintained for over 40 models of backflow prevention valves under the MiniMet and MetCheck ranges. These valves are certified on the Hydromet WM license WM-022473 and Hydromet are subject to annual surveillance by IAPMO Oceania for continued compliance with the WaterMark Certification Scheme

AS/NZS 2845.1 – All MiniMet and MetCheck valves have been tested to, and conform with, the requirements of AS/NZS 2845.1. All MiniMet and MetCheck valves have a classification of either a low or medium hazard rating, as defined in Volume 3 of the NCC, the Plumbing Code of Australia.

Flanged stainless steel pipework – The AS/NZS 4020 test reports also extends to cover the various SS316 flanged pipes manufactured by Hydromet, with these components being available to suit the installation of any backflow prevention valve or water meter assemblies.