Hydromet’s Line of Backflow Prevention Valves, which are locally manufactured in Queensland using high-quality 316 stainless steel. These valves offer significant advantages over traditional ductile iron valves.

Hydromet’s MiniMet Single Check Valves

Designed for Low Hazard Applications these valves are specifically crafted to address low-risk scenarios where backflow prevention is essential. They prevent the reverse flow of water, ensuring that contaminated water doesn’t flow back into the clean water supply.

Features:

- Stainless Steel Construction: Made from high-quality 316 stainless steel, these valves are resistant to corrosion and provide long-lasting performance.

- Watermarked: Hydromet’s MiniMet Single Check Valves meet industry standards and are certified for use.

- Low Maintenance: Plumbers appreciate their durability and minimal maintenance requirements.

- Reliable Protection: They safeguard against backflow incidents, maintaining water quality.

Hydromet’s MetCheck Double Check Valves

Designed for Medium Hazard Applications: These valves offer enhanced protection for scenarios with moderate risk levels. Similar to the MiniMet Single Check Valves, they prevent backflow, ensuring safe water supply.

Features

- Dual Check Mechanism: The double check design provides an extra layer of security against backflow.

- Quality Materials: Constructed from 316 stainless steel, they resist corrosion and maintain their integrity over time.

- Watermarked Certification: These valves undergo rigorous testing to meet industry standards.

- Plumber-Friendly: Designed by plumbers, they prioritize longevity and ease of maintenance.

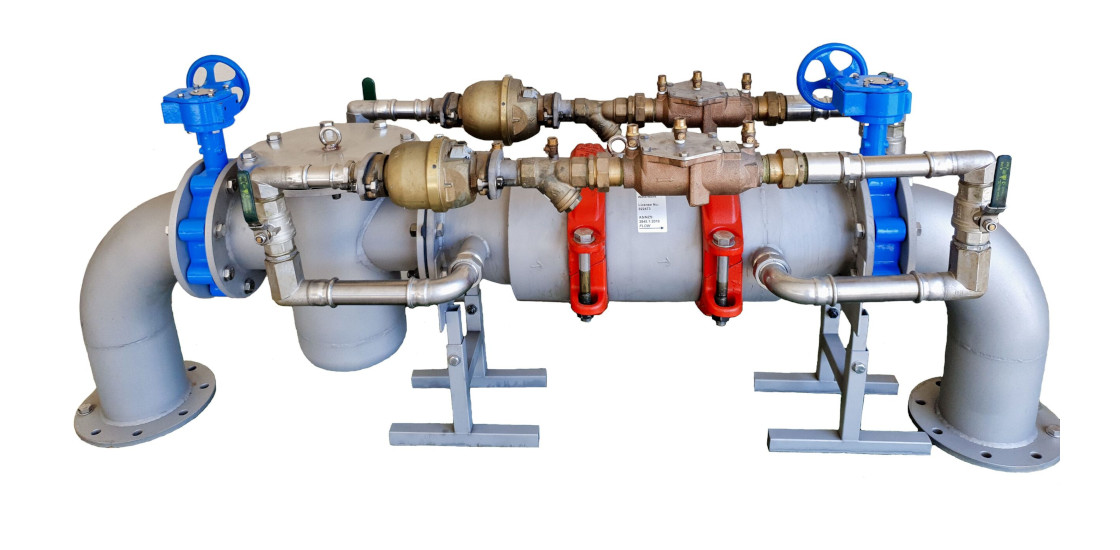

Hydromet’s MetCheck By-Pass Arrangement Valves

- Available in Single Check and Double Check Main Body:

- Single Check By-Pass: Allows for water metering while still servicing fire lines or areas with high water demand.

- Double Check By-Pass: Offers similar functionality but with an additional layer of backflow protection.

- Purpose: By-pass arrangements provide flexibility for managing water flow while maintaining safety.

- Benefits:

- Customizable: Plumbers can tailor the arrangement to specific project requirements.

- Efficient Water Metering: Ideal for scenarios where water measurement is necessary.

- Robust and Reliable: Made from quality materials, they withstand the test of time.

In summary, Hydromet’s valves are not only effective in preventing backflow but also designed with plumbers’ practical needs in mind. Their stainless steel construction ensures longevity, low maintenance, and reliable protection for water systems.

Benefits of a Stainless Steel Valve

- Stainless Steel Corrosion Resistance:

- Stainless steel is highly resistant to corrosion, making it an excellent choice for projects exposed to moisture or chemicals.

- Its durability ensures that components last longer and require less maintenance, ultimately reducing overall costs.

- Unlike ductile iron, stainless steel doesn’t need regular painting or coatings to protect it from rust and corrosion.

- Longevity:

- Stainless steel has a longer lifespan, often outlasting most careers. It’s a “set it and forget it” material that withstands the test of time.

- Ductile Iron Corrosion Limitations:

- Ductile iron, on the other hand, has limited corrosion resistance due to its high carbon content.

- While it’s commonly used in water and wastewater treatment industries, it requires more care and maintenance.

- Lead Times and Costs:

- Stainless steel offers faster lead times and greater flexibility in customization options compared to ductile iron.

- As supply and demand trends have shifted, stainless steel has become a more cost-efficient choice over custom ductile iron.

- Other Properties:

- Ductile iron provides better resistance to corrosion than cast iron, but it still oxidizes faster than stainless steel.

- Additionally, ductile iron is less brittle than steel, making it more resilient to impact forces.

To find out more information about the benefits of stainless steel for water supply continue reading here.